A Real-Life Residential Construction Project in Apokoronas, Chania.

In a residential construction project located in the Apokoronas area, Chania, a significant risk involves delays due to unpredictable weather conditions, particularly during the winter months.

Heavy rainfall and strong winds, common between November and March, can severely affect exterior construction activities such as foundation work, masonry, and roofing. In this region, where coastal weather patterns can shift quickly, construction sites often face downtime when exposed materials and structures cannot be adequately protected from the elements.

These delays not only extend the overall project timeline but also increase labor costs, material wastage, and the likelihood of subsequent scheduling conflicts with other subcontractors.

To mitigate this risk, a combination of seasonal scheduling and contingency planning is essential. Construction teams should plan weather-sensitive activities during the dry months (April to October) when the likelihood of disruptions is significantly reduced.

Additionally, building in buffer periods into the project schedule allows for unexpected delays without affecting the overall completion date. Temporary protective structures, such as tarpaulins or scaffolding covers, can also be used to shield ongoing work from light rain, ensuring that productivity continues in less severe conditions. These measures help maintain progress, reduce costs from weather-related damage, and improve the overall efficiency of the construction process in Apokoronas.

Table 1: Identified Construction Risks in Apokoronas Residential Project

| Risk ID | Risk Type | Description | Likelihood | Impact | Risk Level |

|---|---|---|---|---|---|

| 1 | Weather Delays | Rainfall causing delays in exterior construction activities | High | Medium | High |

| 2 | Material Delivery Delays | Delays in material delivery due to supply chain disruptions or transportation issues | Medium | High | High |

| 3 | Labor Shortages | Availability of skilled labor may be impacted by demand in the peak construction season | Low | High | Medium |

Table 2: Mitigation Strategies for Construction Risks

| Risk ID | Mitigation Strategy | Description | Expected Effectiveness |

|---|---|---|---|

| 1 | Seasonal Scheduling | Plan exterior works for the dry season (April-October) to minimize weather-related delays | High |

| 1 | Contingency Planning | Include buffer time in the construction timeline to account for potential weather disruptions | Medium |

| 2 | Material Pre-ordering | Order critical materials in advance to avoid delays caused by supply chain issues | High |

| 3 | Contract Agreements with Multiple Subcontractors | Secure agreements with additional labor providers to reduce dependency on a single subcontractor | Medium |

A Real-Life Paradigm: Passive House Construction in Akrotiri, Risks & Mitigation Plans.

In the area of Akrotiri, Chania, passive house construction projects face unique risks due to the highly specific design requirements and performance standards.

One major risk is related to achieving the required airtightness and thermal insulation levels. The local climate, which includes high temperatures in summer and moderate winters, can make it challenging to ensure that the building envelope performs to the stringent passive house standards.

Incorrect installation of insulation materials or failure to properly seal air leaks can lead to increased energy consumption, defeating the purpose of a passive house. These errors can result in higher heating and cooling loads, compromising the energy efficiency and comfort levels the project aims to achieve.

Table 3: Construction Risks in Passive House Project – Akrotiri, Chania

| Risk ID | Risk Type | Description | Likelihood | Impact | Risk Level |

|---|---|---|---|---|---|

| 1 | Airtightness Compromise | Inadequate sealing or material selection leading to air leaks, affecting the thermal performance of the passive house | Medium | High | High |

| 2 | Improper Insulation Installation | Incorrect placement or inadequate quality of insulation materials that result in thermal bridges and reduce energy efficiency | Medium | High | High |

| 3 | Window and Door Installation Faults | Poor installation of high-performance windows and doors, which are crucial for minimizing heat loss and maintaining airtightness | Low | High | Medium |

| 4 | Moisture Control Failures | Lack of proper vapor barriers and ventilation leading to condensation issues, mold growth, and potential structural damage | Medium | High | High |

| 5 | Supply Chain Issues for Passive House Materials | Delays in sourcing specialized passive house materials such as triple-glazed windows, airtight membranes, and high-quality insulation | High | Medium | High |

Table 4: Mitigation Strategies for Passive House Construction Risks

| Risk ID | Mitigation Strategy | Description | Expected Effectiveness | Cost Impact |

|---|---|---|---|---|

| 1 | Detailed Airtightness Planning & Testing | Develop a comprehensive airtightness plan before construction and conduct regular blower door tests to identify and fix air leaks during construction | High | Moderate |

| 1 | High-Quality Sealing Products | Use certified, high-quality airtight tapes, membranes, and sealants specifically designed for passive houses | High | Moderate |

| 2 | On-site Training for Insulation Installation Teams | Provide specialized training to construction teams on proper insulation installation to avoid thermal bridges and ensure high-performance insulation | High | Low |

| 2 | Layered Insulation Approach | Implement multi-layered insulation systems to enhance thermal resistance and minimize errors during installation | Medium | High |

| 3 | Specialist Window and Door Contractors | Hire certified passive house window and door installers who understand the importance of precision in fitting these key components | High | High |

| 4 | Vapor Barrier and Ventilation System Installation | Ensure proper installation of vapor barriers and mechanical ventilation systems to control moisture and prevent condensation and mold | High | Moderate |

| 5 | Early Ordering and Multiple Supplier Contracts | Pre-order specialized materials early in the project timeline and secure agreements with multiple suppliers to minimize the risk of supply chain disruptions | Medium | Moderate |

Example Narrative:

In an Akrotiri passive house construction project, a significant challenge was ensuring the building met passive house standards for airtightness and thermal insulation. During construction, the team found that insufficient sealing in the building envelope caused air leaks, which affected the overall energy efficiency of the structure.

This risk was mitigated by using certified, high-quality airtight tapes and conducting regular blower door tests to detect and fix air leakage points early. Furthermore, to prevent improper insulation placement, the construction team received specialized training on insulation installation, ensuring the avoidance of thermal bridges and increasing the overall energy performance of the passive house.

Another critical risk was related to the installation of high-performance windows and doors. Poor installation can lead to heat loss and moisture problems, which would significantly compromise the passive house’s efficiency. To address this, the project employed certified installers who were specifically trained in fitting passive house components.

Additionally, vapour barriers and an effective ventilation system were implemented to ensure moisture control, preventing mold and protecting the structural integrity of the building. These mitigation strategies ensured the passive house met performance standards and achieved long-term energy efficiency.

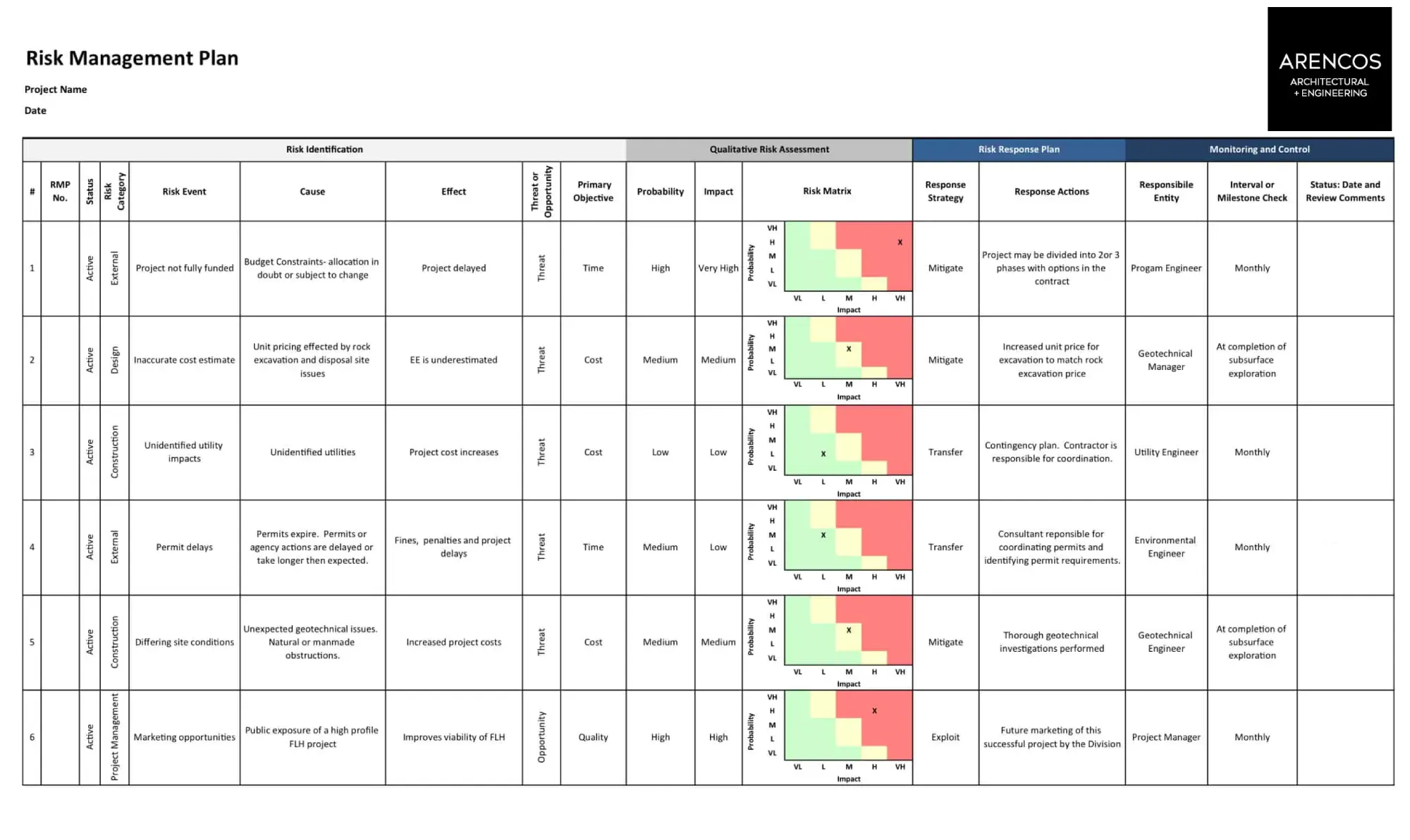

ARENCOS' Risk Mitigation Plan

ARENCOS’ Construction Management and Mitigation Plan leverages cutting-edge technologies like Building Information Modeling (BIM), Artificial Intelligence (AI), and real-time data from the construction site to optimize project efficiency and minimize risks. By integrating BIM, ARENCOS creates detailed 3D models of the building, allowing for accurate planning, visualization, and coordination across various project phases. This digital representation also enhances collaboration among architects, engineers, and contractors.

The use of AI further strengthens decision-making by analyzing vast amounts of project data, predicting potential challenges, and offering proactive solutions. AI-driven algorithms can optimize scheduling, cost management, and resource allocation by learning from historical project data and real-time conditions.

Additionally, real-time data from the construction site—captured through sensors, drones, and IoT devices—feeds directly into the BIM and AI systems. This continuous flow of data ensures that any deviations from the plan are detected early, allowing for immediate corrective actions. By combining BIM, AI, and real-time site data, ARENCOS ensures a highly responsive, adaptive approach to construction management that mitigates delays, reduces costs, and ensures top-tier project delivery.

This holistic strategy makes the construction process more resilient and agile, aligning with ARENCOS’ commitment to innovation and sustainable development.

Further Reading

FEMA Risk Management – This page offers extensive guidance on identifying and assessing risks in construction, with tools for hazard resilience, climate resilience, and earthquake risk. It also includes detailed information on mitigation planning and how to prioritize risks to minimize financial losses. www.fema.gov

Building Resilient Infrastructure and Communities (BRIC) – This resource from FEMA focuses on infrastructure resilience, providing tools and grants for communities to develop projects that reduce risks from natural disasters, including construction-related risks. www.fema.gov/bric

Risk Management in Construction Projects – A resource from the European Union discussing construction risk management, covering risk assessment techniques and real-time project data integration. ec.europa.eu

Construction Risk Mitigation Techniques – From the Construction Management Association of America (CMAA), this page explains key strategies to mitigate risks, including best practices for project management. www.cmaanet.org